Nowadays a truly good tobacconist sadly is a rare thing here but decades ago The Netherlands boasted lots of them. Specialist stores where the knowledge of the salesmen was of crucial importance because the clients relied on it. These days we can simply look up information on the digital highway but back then you had to trust the expertise of your tobacco vendor. One of the most well known and respected tobacconists in that time was G. de Graaff in the political heart of our small country: The Hague.

Nowadays a truly good tobacconist sadly is a rare thing here but decades ago The Netherlands boasted lots of them. Specialist stores where the knowledge of the salesmen was of crucial importance because the clients relied on it. These days we can simply look up information on the digital highway but back then you had to trust the expertise of your tobacco vendor. One of the most well known and respected tobacconists in that time was G. de Graaff in the political heart of our small country: The Hague.

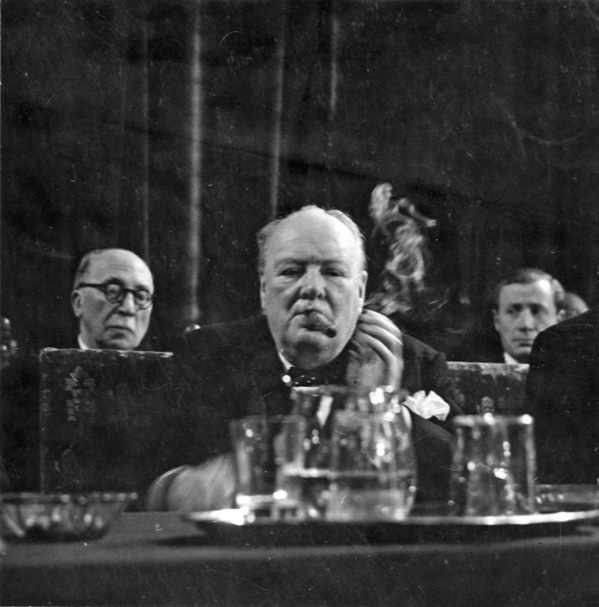

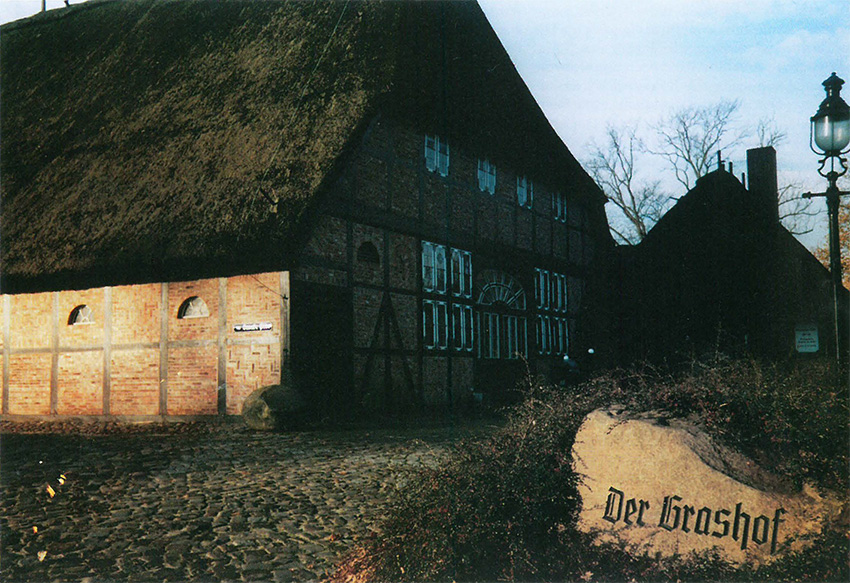

Founded in 1928 by Gerard de Graaff (who was later joined by his son Frits de Graaff) the business was located at the Heulstraat no. 27. Not far from Noordeinde Palace, Council of State, Council for the Judiciary and the Binnenhof in the old city centre. They got well-known both at home and abroad very quickly, mainly because of their excellent house-brand G. de Graaff cigars, which were made by 5 different cigar factories in The Netherlands. Even the legendary Winston Churchill had heard of them. Dutch Pipe Smokers Forum member Willem tells: “My father, who had a high ranking job at the Ministry of Finance, knew De Graaff very well because he always bought his cigars there. So when Churchill visited The Hague for the Congress of Europe in 1948 my father arranged some special Cuban cigars for him which came, of course, from De Graaff.” Other famous people who visited the store throughout the years were amongst others Bill Clinton, prince Bernard, Josip Tito, François Mitterrand and Konrad Adenauer.

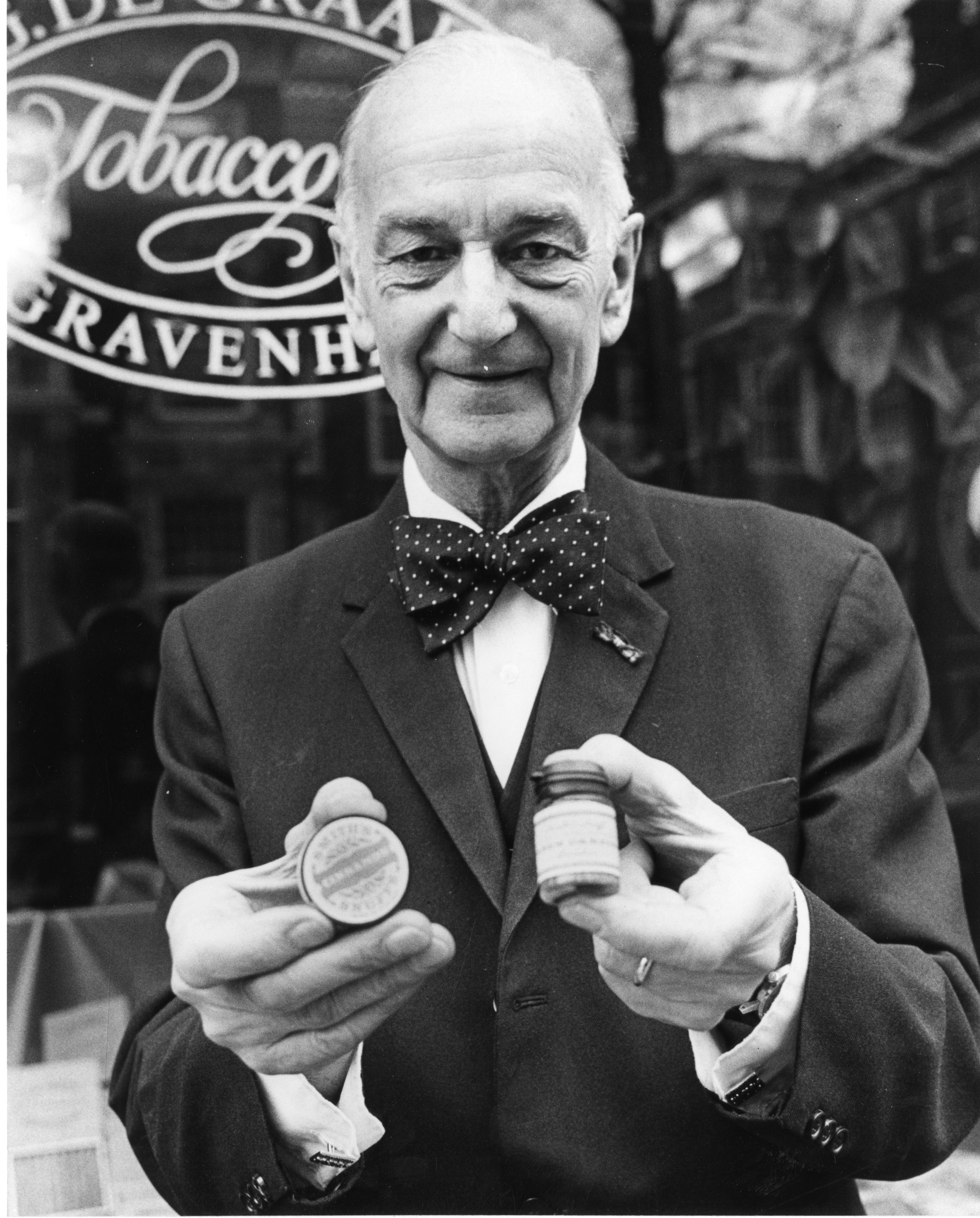

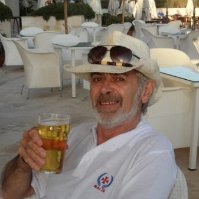

After the war the sons of Frits, Robbert and Gerard de Graaff, entered the business. But soon father Frits realized that letting Gerard and Robbert work together was not a good idea. So Gerard kept himself busy with the production side and Robbert took care of the sales in the store. Frits de Graaff was a remarkable man, a real old world salesman. He lived above the store and was always impeccably dressed, like the true gentleman he was, with his trademark bow tie. Also he was a man of principles, if he did not believe in a brand he would not sell it. Willem tells: When I had my practice in The Hague, around 1976-1980, the De Graaff store had something special, something chic. In that time I smoked MacBaren. When I asked for such a tin at the store Mr. Frits always said that the tobacco contained too much glycerine “Which is not good for your throat!”. Like the polite man I was and still am I then bought a tin of Flying Dutchman, which was much better according to him.

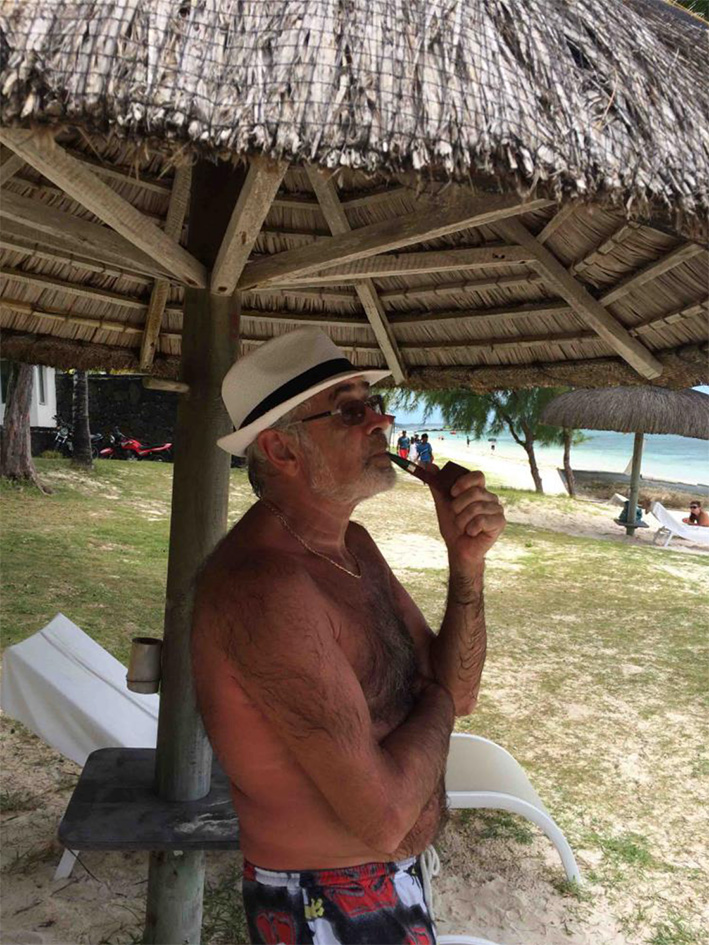

Also I know that De Graaff did not sell Peterson because of the P-Lip mouthpiece, the often shabby finish, the many fills and because of the long time it took to break in a pipe. I think he liked Dunhill better, Dutch Pipe Smokers Forum member Rob tells: Once I was in the store together with Mr. De Graaff. While talking he took a Dunhill pot-shaped pipe out of his pocket and told this was his father’s favourite pipe. You could see the pipe was old and that it had once been a heavy sandblasted Shell Briar but because of the use the surface had become smooth. After his death he kept the pipe and smoked it several times a week. As far as tobacco went Frits de Graaff liked latakia very much. Rob tells: I remember well that I was a boy of about 18 years old when I stepped inside the store to buy a pipe. When the conversation drifted towards pipe tobacco he pointed out “the only tobacco” latakia to me. Besides the pipe I let myself be persuaded to also buy a tin with latakia and indeed, I was swept away. Back in those days that fine tobacco was significantly more expensive than e.g. Mac Baren so I smoked latakia in moderation, because I had to pay for it from the proceeds of my newspaper round. Sadly Frits de Graaff passed away in 1996, Robbert took over the business but he sold the store in 2005. The new owners tried their best but the grandeur of days past never really came back. Just recently I learned that the shop at the Heulstraat no. 27 is closing, the owners want to merge it with another store of them at another location.

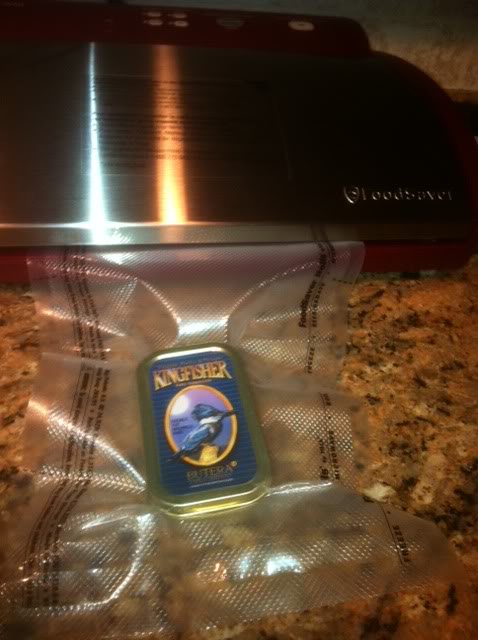

My own story with De Graaff began in 2011. I was just discovering the realm of the dark leaf when I began exchanging messages and tobacco samples with Klaas. Because of him I was able to try wonderful blends like Balkan Sobranie Original Smoking Mixture, GL Pease Westminster and De Graaff Kegelbaan Mixture and Back in Town. The last 2 were house-blends. I knew sh*t about pipe-tobacco in those days but what I noticed was that they were all of very high quality. Klaas saw that I really enjoyed the De Graaff tobaccos, generously gave me some tins and told the following story: I discovered the De Graaff house-blends fairly late, in the 90’s, but I was immediately smitten. I really invested in them and bought loads of tins. Suddenly at the end of the 90’s I was told in the store that the house-blends were being discontinued. I panicked a bit and decided to buy all the tins I could get my hands on. In the store and in other tobacco shops in The Netherlands who also carried the De Graaff house-blends. Of course during the years I smoked a lot of them but I still have some left. The only thing I always wondered was where those fabulous tobaccos were made. It was a well kept secret that De Graaff never told to anyone..

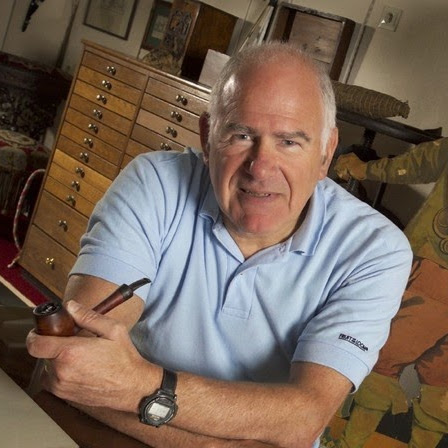

Throughout the years I smoked some excellent De Graaff blends which were given to me by Klaas and another forum member. Also whenever I was in a tobacco-shop I asked if they had some old tins stashed away somewhere. Now and then I even got lucky and I was able to buy some old De Graaff tobaccos meant for home-blending, which I did and created lovely blends with them. But when I heard that the actual shop at the Heulstraat was closing down I decided to write a blogpost about De Graaff and do some research. At that point all I had were the names of the 2 sons of Frits, Gerard and Robbert. So I asked yet another forum member, Rudi, who had a tobacco-shop in Middelburg for years, if he had a contact address or something like that. He didn’t but he pointed me towards a Belgian man who made cigars for Gerard. I contacted him but he knew very little, only that, very sadly, Robbert had passed away a few years ago. Damnit! Robbert was the mastermind behind the pipe-tobaccos, so I was pretty gutted when I heard that. Then I decided to use an old contact of mine, Louis Bracco Gartner, founder of the Historical Tobacco Museum in Delft and the Tobacco History website. He helped me before with my Diepenveensche Tabaks Centrale blogpost and when I mailed my questions to him he responded with “call me, I know more.” So I phoned him and he turned out to be friends with Gerard de Graaff. I got the mail-address of the latter, contacted him a couple of times and got no response besides a mail which said I had the wrong man and that he did not know anything about pipe-tobacco..

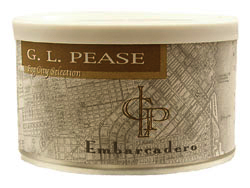

So I phoned Louis again, told him this (according to him the mail-address was correct) and said I only wanted to know where De Graaff house-blend pipe tobaccos were made. “Oh but I know that!” “Ehmm.. Excuse me??” “Yes I know that, the house-blends were made by Dunhill in London.” Wowwww…. I was gobsmacked.. Made by Dunhill.. Hmmm, the 60’s and 70’s ok, Dunhill was still Dunhill, but during the 80’s and 90’s Dunhill blends were made by Murray. Those tobaccos were not highly acclaimed, not just by me (I smoked some) but also by others. The De Graaff blends I smoked dated from the 90’s and were of exceptional quality, way better than Murray-era Dunhill. Then from out of the back of my head I remembered I read something on the Dunhill page of the great late John Loring. Something about blends still being made (in the 80’s and 90’s) at the Dunhill Duke Street shop: One exception to the 1981 blending transfer (from Dunhill to Murray) should be noted. The Dunhill Duke Street shop continued to offer custom blending for the next two decades and as part of that continuation, a small batch blender in London (I suspect with Dunhill associations) continued to produce a number of My Mixture blends available only from the Duke Street shop. So it could very, very well be that that was the way the De Graaff house-blends were made.

So I phoned Louis again, told him this (according to him the mail-address was correct) and said I only wanted to know where De Graaff house-blend pipe tobaccos were made. “Oh but I know that!” “Ehmm.. Excuse me??” “Yes I know that, the house-blends were made by Dunhill in London.” Wowwww…. I was gobsmacked.. Made by Dunhill.. Hmmm, the 60’s and 70’s ok, Dunhill was still Dunhill, but during the 80’s and 90’s Dunhill blends were made by Murray. Those tobaccos were not highly acclaimed, not just by me (I smoked some) but also by others. The De Graaff blends I smoked dated from the 90’s and were of exceptional quality, way better than Murray-era Dunhill. Then from out of the back of my head I remembered I read something on the Dunhill page of the great late John Loring. Something about blends still being made (in the 80’s and 90’s) at the Dunhill Duke Street shop: One exception to the 1981 blending transfer (from Dunhill to Murray) should be noted. The Dunhill Duke Street shop continued to offer custom blending for the next two decades and as part of that continuation, a small batch blender in London (I suspect with Dunhill associations) continued to produce a number of My Mixture blends available only from the Duke Street shop. So it could very, very well be that that was the way the De Graaff house-blends were made.

Now about those house-blends. I don’t know precisely when the first pipe-tobacco house-blends were made but Rob has to say this: It must have been 1967 when I first visited De Graaff. I remember that in the room where the pipes were there also was a display with pipe tobaccos, sold under their own name. A couple of years ago I luckily had downloaded through the Wayback machine the original house-blend descriptions from the old De Graaff website. Here they are with notes from myself and pictures:

-Abu Riha-

-Abu Riha-

Exceptional aromatic flake with a good deal of Latakia, as well as Turkish, and Red Virginia tobaccos. Excellent composition over a glass of Single-Malt whiskey. I smoked some tins of this one and I can best describe it as the prefect marriage between Smoker’s Haven Krumble Kake and Esoterica’s Penzance. In fact, it looked and tasted so much like those blends that I decided to mail J.F. Germain (and added some pictures) and they responded: These are very interesting pictures, we did not make any tobacco for De Graaff but I understand why you ask the question the tin and the tobacco look like Penzance from years ago.

-Back In Town-

-Back In Town-

One of our most successful mixtures, an ex-cigarette-smoker assisted in composing this blend. A fine composition of light and dark Virginia’s, Syrian Latakia, Kavalla (Macedonian tobacco) and Carolina Cavendish. A medium mixture with a pleasant flavour. A pleasant flavour indeed! This is one of the De Graaff classics, Syrian latakia, Kavalla, nomnomnom! Perfectly blended, very harmonious.

-Carl’s Own Blend-

-Carl’s Own Blend-

Carefully composed by the HOUSE OF GOOD TASTE. Is the choice of a man of FINE TASTE. Born and bred in the THEATRE OF ROYAL TASTE. Full-flavoured mixture on the basis of Virginia tobaccos (Flue Cured East Carolina and Georgia) and a small quantity of Latakia. Sadly I never smoked this blend.

-Coronation-

-Coronation-

This blend has been already produced for more than a century for the discerning smoker. Very mild, not burning the tongue. For the morning. I once had a sample of this blend but can’t remember it any more..

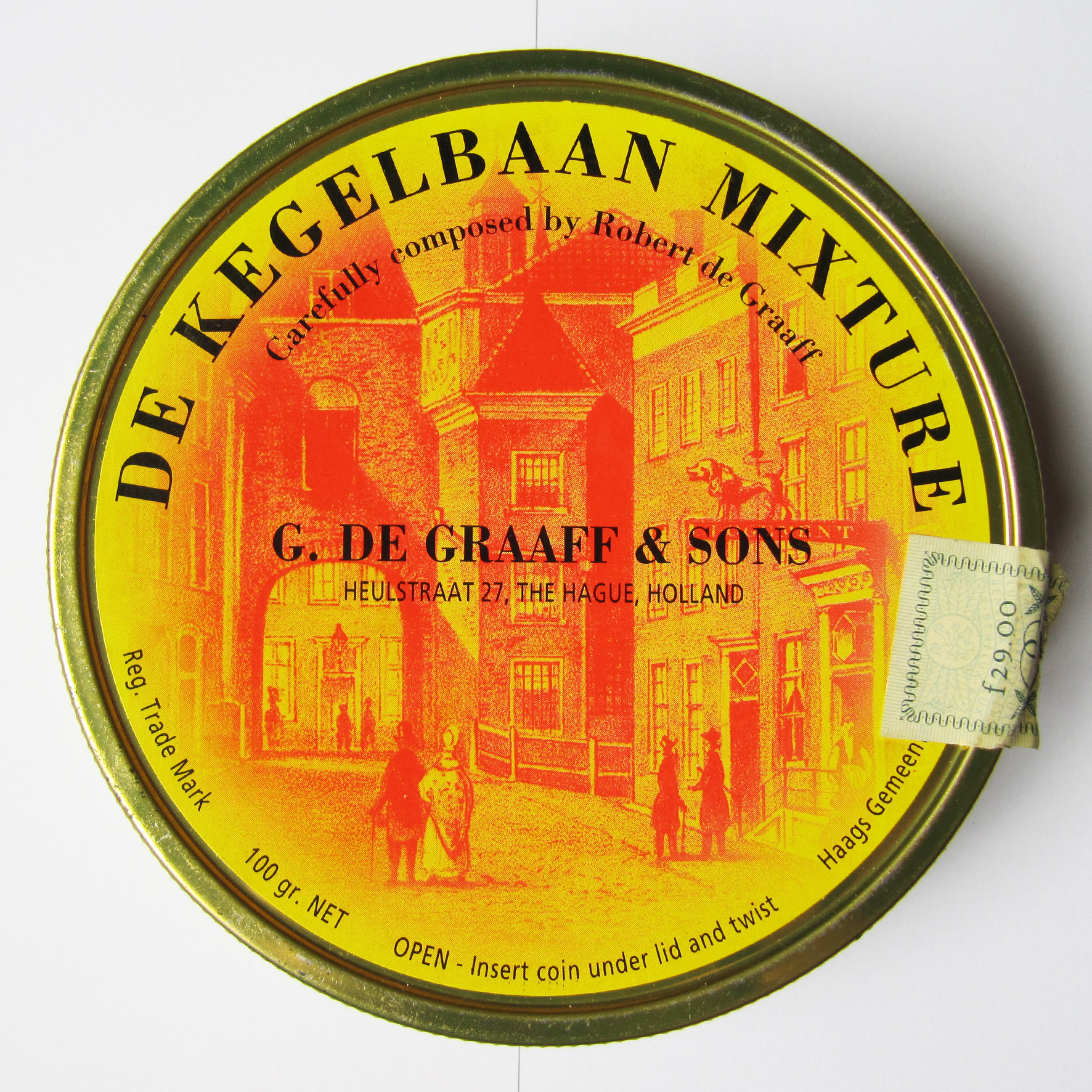

-De Kegelbaan-

-De Kegelbaan-

An unique blend of first class tobaccos: Syrian Latakia, Old Belt Virginia, Brown Cavendish and Turkish tobaccos (Yenidshe). Mild taste, cool, slow burning. This is another big classic, I just finished a tin and only 1 word: exceptional. And not just a couple of times, no every time! The Yenidje is immediately recognizable (for those that have smoked Yenidje Supreme) and sings together nicely with the Syrian Latakia and Virginia’s. The Brown Cavendish mellows it all out a bit. I think that the creator Robbert De Graaff tried to imitate the old Balkan Sobranie with this one if I see the ingredients. And for me he absolutely succeeded!

-Golden Virginia-

-Golden Virginia-

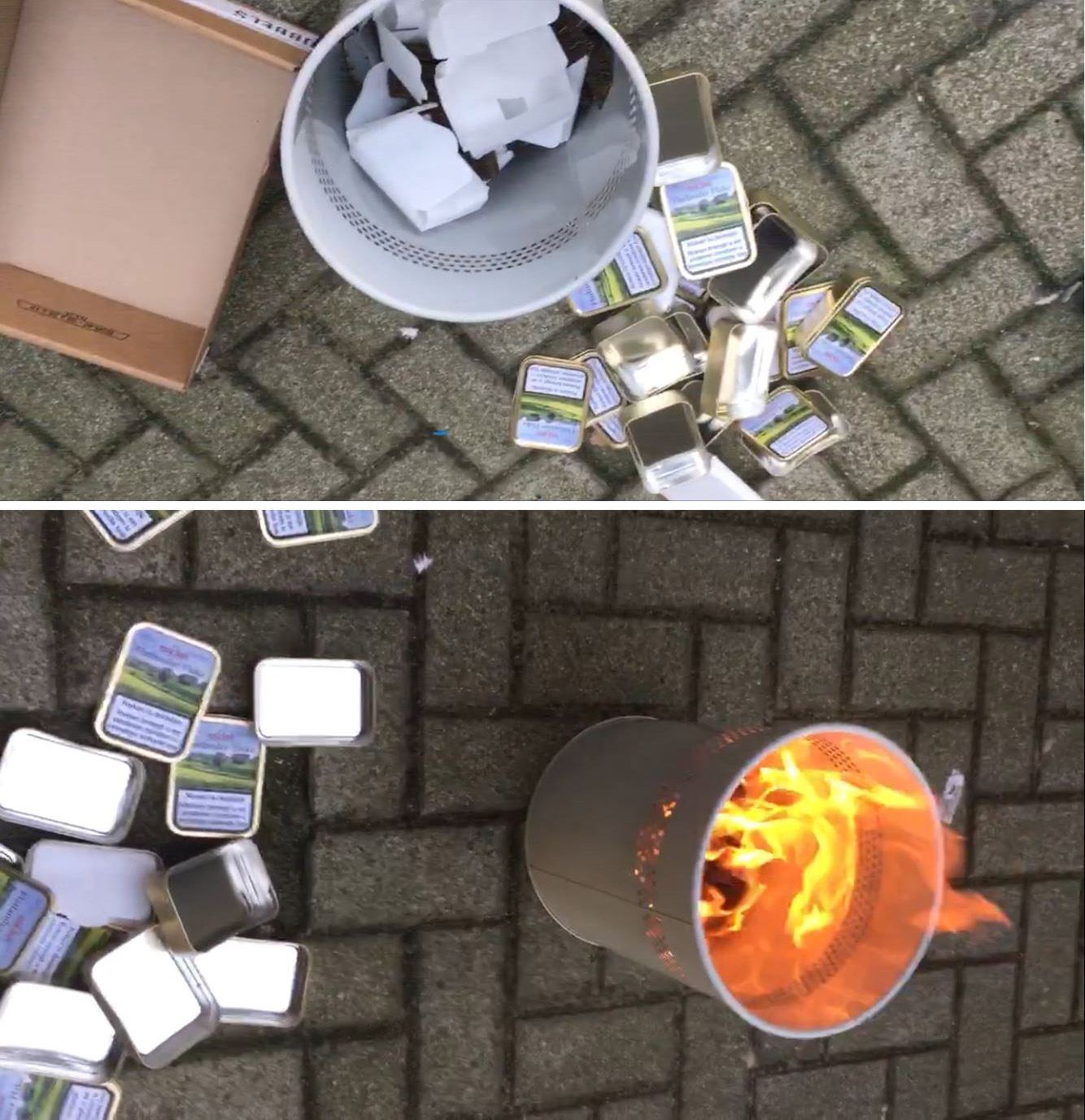

Cool, somewhat sweet Virginia Bright Leaf. This is one of the oldest varieties of “flue cured” tobacco. Pleasant taste. I used this blend a couple of times in home-made mixtures. It reminded me a bit of Dunhill Flake, but then in a ribbon-cut. I had several tins but threw them away in a fit of cleaning rage before I could take a picture..

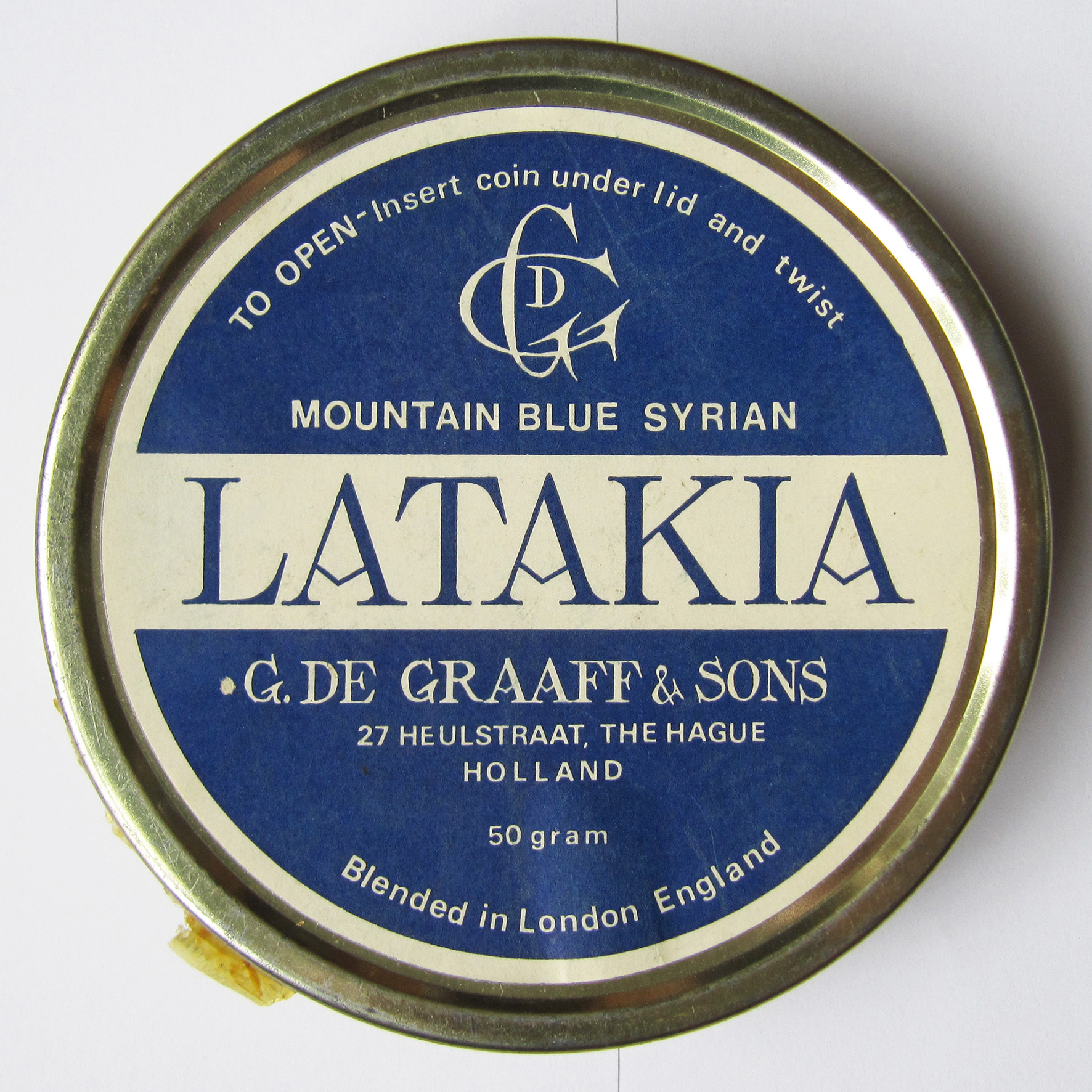

-Latakia-

-Latakia-

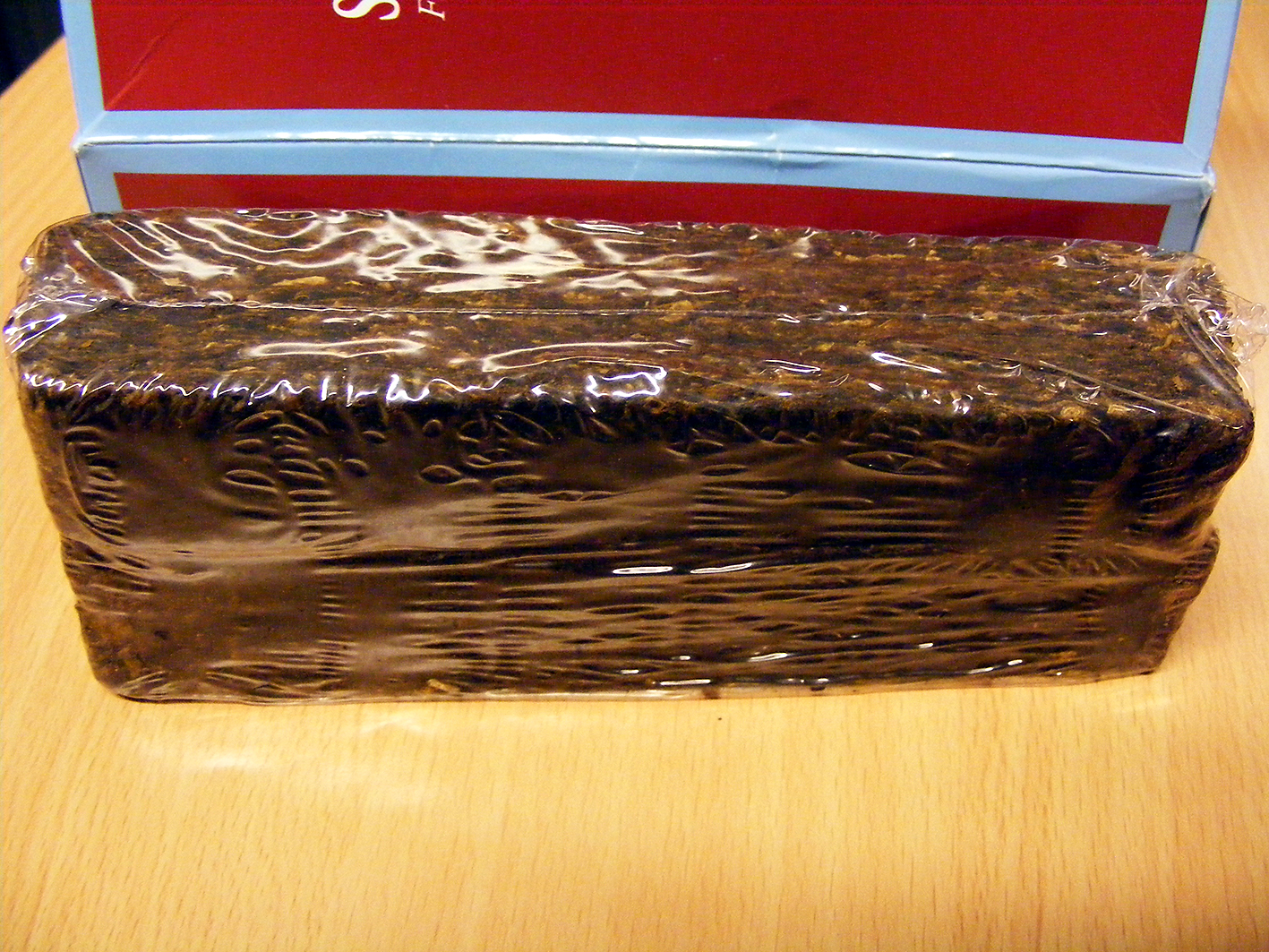

Jebeli is also called “Abu Riha” (Father of the pleasant smell) by the Syrian population. The flavour is acquired by drying the tobacco over a fire of camel-dung (nice commercial story but not the truth..). Tobacco especially for mixing. And that is precisely where I use it for. When you open a tin, whoaaa… It smells so damn good! Also when you smoke it straight it is very yummie. On the tin it says Mountain Blue Syrian, of course made famous by Balkan Sobranie 759, the stuff of legends.

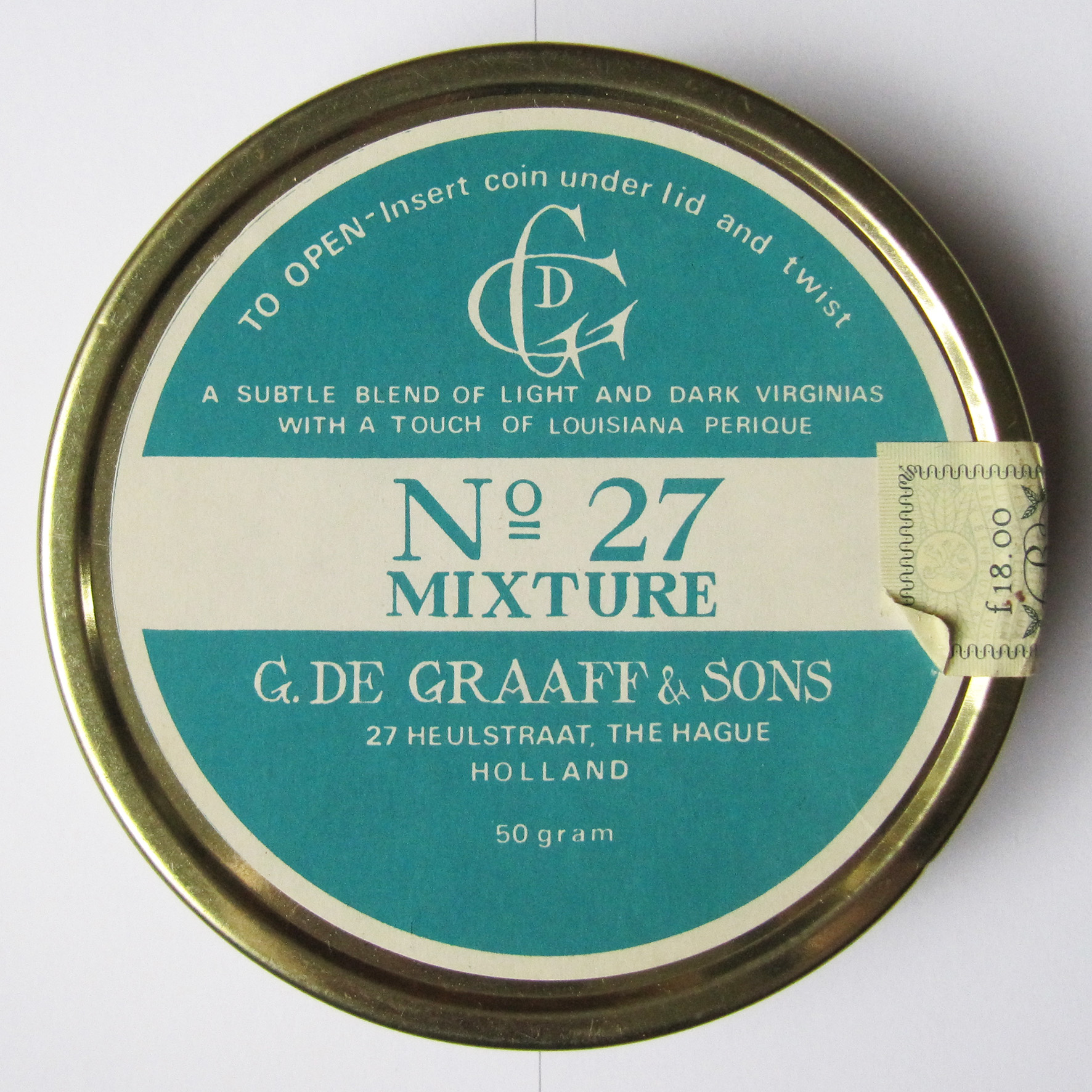

-No 27-

-No 27-

This tobacco gives evidence of craftsmanship. Composed of the best Golden- and Middle Belt Virginias, Corolina Cavendish, completed with a pinch of Lousiana Perique, for the perfect taste. Especially made for those smokers who prefer a Virginia blend. This tobacco is particularly aromatic and yet mild of taste. The only thing I can remember about this one is “tastes a bit like Dunhill Elizabethan“.

-Perique-

-Perique-

The Perique tobacco is unique, its history is dating back to the Choctaw and Chicasaw Indians. It adds a spicy flavour to all tobacco blends. It is without “bite”, although it is far too heady to be smoked straight. Well, Aleister Crowley did! I use it only for home-blending.

-Seamen’s Club-

-Seamen’s Club-

Matured dark Virginia. This warm, dark tobacco is mild in taste and can be smoked pure or in mixtures. Unadulterated Red Virginia, I used it many times in home-blending for some Virginia backbone.

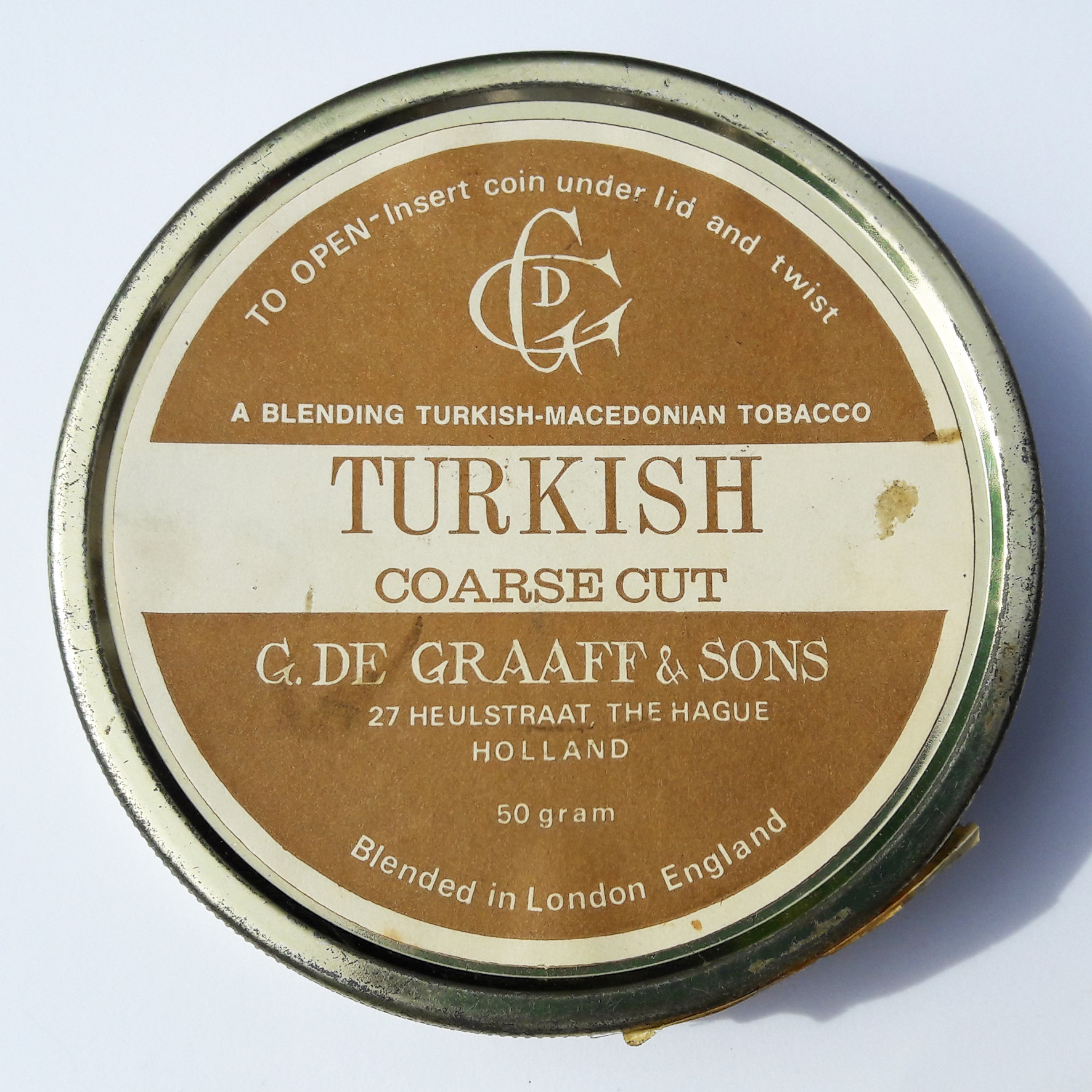

-Turkish-

-Turkish-

Excellent burning qualities. Suitable for mixing, can also be smoked pure. Extremely mild with sweet undertone. I used this once in home-blending, it tastes like there is some Kavalla in it.

De Graaff also had house-brand pipes. Several Dutch Pipe Smokers members have such a smoking device. They were made in London and later in France. But where? No idea.. So I mailed Louis again, he asked around and came with a name: GDD! Ehrrr, I guess you mean GBD? He wasn’t sure but I now know it was GBD indeed, just look at the picture beside this paragraph. Where the pipes were made in France I sadly do not know..

De Graaff also had house-brand pipes. Several Dutch Pipe Smokers members have such a smoking device. They were made in London and later in France. But where? No idea.. So I mailed Louis again, he asked around and came with a name: GDD! Ehrrr, I guess you mean GBD? He wasn’t sure but I now know it was GBD indeed, just look at the picture beside this paragraph. Where the pipes were made in France I sadly do not know..

Of course there is much more to tell about De Graaff, especially their cigars, but since this is a pipe-smoking blog it is enough for now. One last thing, here is a PDF document of 2 interesting old booklets/flyers from De Graaff, in Dutch.. I would like to thank all the forum members and people who have helped me and made this blogpost possible!